Beautiful Info About How Do You Clean A PCB

Drying An Essential Step To Cleaner PCBs Electronics World

So, You've Got a Dirty PCB? Let's Clean It Up!

1. Why bother cleaning a PCB anyway?

Alright, let's face it. PCBs (Printed Circuit Boards) aren't exactly known for their pristine beauty. They're the unsung heroes inside our gadgets, quietly conducting electricity and making the magic happen. But like any hard worker, they can get a little grimy over time. Dust, flux residue, spilled coffee (guilty!), and other contaminants can accumulate, potentially leading to performance issues or even complete failure. No one wants that! That's why understanding how you clean a PCB is essential for maintenance. A clean PCB is a happy PCB, and a happy PCB makes for a happy gadget (and a happy you!).

Think of it like this: imagine you're trying to run a marathon in shoes filled with pebbles. Not exactly ideal, right? Similarly, a PCB covered in gunk struggles to operate efficiently. Cleaning it removes those "pebbles," allowing the board to perform at its best. And hey, a clean PCB just looks nicer, doesn't it?

Moreover, in certain applications, especially those dealing with high voltages or sensitive signals, contaminants can create conductive paths where they shouldn't be. This can lead to shorts, signal leakage, and a whole host of electronic gremlins that nobody wants to deal with. So, prevention is truly better than cure in this context.

In a nutshell, learning how you clean a PCB is a preventative measure that helps extend the life of your electronics, improves their performance, and avoids potentially catastrophic failures. Plus, its a satisfying little project. Sort of like giving your electronic friends a nice bath!

How To Clean A PCB Using An Ultrasonic Cleaner YouTube

Gather Your Supplies

2. What do you need to clean PCBs?

Before you dive headfirst into scrubbing your PCB, let's gather the necessary tools. Think of this as assembling your cleaning arsenal. Having the right supplies will make the process much smoother and prevent you from damaging the delicate components on the board. Remember, we're aiming for a gentle and effective clean, not electronic demolition!

First up: the cleaning solution. Isopropyl alcohol (IPA) with a concentration of 90% or higher is your best friend here. It's a great solvent for dissolving flux residue and other contaminants, and it evaporates quickly, minimizing the risk of water damage. Avoid using household cleaners or anything that might leave a residue behind.

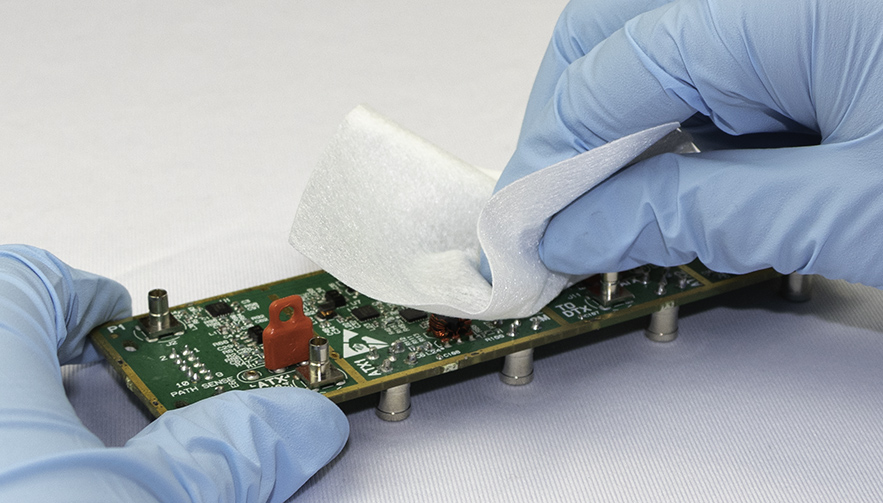

Next, you'll need some application tools. A soft-bristled brush (an old toothbrush works great!), cotton swabs, and lint-free wipes are perfect for gently scrubbing and wiping away the grime. For more stubborn residue, consider using a specialized PCB cleaning brush. Never use abrasive materials, as these can scratch the surface and damage the components.

Finally, depending on the level of cleaning required, you might also want to have some distilled water on hand for rinsing (make sure the board is completely dry afterward!), compressed air for blowing away dust and debris, and some magnifying glasses or a microscope to inspect the board closely. A well-lit workspace is essential as well!

The Step-by-Step PCB Cleaning Process

3. How to gently clean the PCB?

Alright, you've assembled your cleaning arsenal. Now comes the actual cleaning. Remember, patience and a gentle touch are key here. We're not trying to scrub the paint off a battleship; we're delicately removing contaminants from sensitive electronic components. So, take your time, and don't rush the process. Safety First though, disconnect from power before cleaning!

Begin by applying a generous amount of isopropyl alcohol to your brush or cotton swab. Gently scrub the PCB surface, paying particular attention to areas with visible residue or dirt. Use circular motions and avoid applying excessive pressure. For hard-to-reach areas, a cotton swab dipped in IPA can work wonders.

After scrubbing, use a lint-free wipe to carefully wipe away the dissolved contaminants. If the residue is particularly stubborn, you may need to repeat the process several times. If you're using distilled water for rinsing, make sure to thoroughly dry the PCB afterward. Compressed air can be helpful for blowing away any remaining water droplets.

Finally, inspect the PCB closely with a magnifying glass or microscope to ensure that all the contaminants have been removed. If you spot any remaining residue, repeat the cleaning process as needed. Once you're satisfied that the board is clean, allow it to air dry completely before reassembling your device.

How To Build PCB Kits A Complete Guide For Beginners GlobalWellPCBA

Dealing with Stubborn Residue

4. What if IPA doesn't work?

Sometimes, despite your best efforts, certain residues refuse to budge. Flux, in particular, can be a real pain to remove, especially if it's been left on the board for a long time. In these cases, you might need to employ some more advanced cleaning techniques. But fear not, even stubborn residues can be conquered with the right approach.

One option is to use a specialized flux remover. These solvents are specifically designed to dissolve flux residue without damaging the PCB. Follow the manufacturer's instructions carefully, as some flux removers can be quite aggressive. Ensure that the area is well-ventilated when using specialized cleaners.

Another technique involves using a soft toothbrush and gentle scrubbing action, combined with a flux remover. However, be very careful not to damage any components on the PCB. Slow, controlled movements are essential. If you are dealing with a very delicate board, using a combination of heat (from a hot air gun or soldering iron) and flux removal may also help loosen the residue.

If all else fails, you can consider using an ultrasonic cleaner. These devices use high-frequency sound waves to create tiny bubbles that dislodge contaminants from the PCB. However, ultrasonic cleaning can be quite harsh, so it's best to reserve it for PCBs that can withstand the treatment. As a last resort, consider professional PCB cleaning services. These services have specialized equipment and expertise to clean even the most stubborn PCBs.

Drying and Inspection

5. How to ensure it's completely dry before use?

You've cleaned your PCB, battled the stubborn residues, and are finally ready to see the fruits of your labor. But hold on a second! Before you proudly reassemble your device, it's absolutely crucial to ensure that the PCB is completely dry. Any residual moisture can cause corrosion, short circuits, and other nasty problems, undoing all your hard work. Consider this the final, but vital, step in the process.

The simplest way to dry a PCB is to let it air dry. Place the board in a well-ventilated area and allow it to sit for several hours, or even overnight. To speed up the process, you can use a fan to circulate air around the board. Just be sure to keep the fan clean to avoid blowing dust onto your freshly cleaned PCB. A clean environment helps with drying.

For a quicker drying method, you can use a low-heat oven or a heat gun. If using an oven, set it to the lowest possible temperature (ideally below 150F or 65C) and place the PCB inside for 15-30 minutes. If using a heat gun, keep it moving and avoid focusing the heat on any one spot for too long. Overheating can damage the components on the board.

Once the PCB is dry, give it one final inspection. Use a magnifying glass or microscope to check for any remaining residue or moisture. If you spot anything, repeat the cleaning and drying process as needed. Only when you are absolutely certain that the PCB is clean and dry should you reassemble your device.

FAQ

6. Got burning questions about cleaning PCBs? Let's tackle some common issues.

Cleaning PCBs can sometimes feel like navigating a minefield of potential problems. But don't worry, we're here to help you defuse those cleaning dilemmas. Let's answer some of the frequently asked questions about cleaning your PCB to get it back in tip-top shape.

Q: Can I use regular tap water to clean my PCB?

A: Nope! Tap water contains minerals and impurities that can leave residue behind and even cause corrosion. Always use distilled water if rinsing is necessary, and ensure the board is completely dry afterward.

Q: What if I accidentally spill water or other liquids on my PCB?

A: Time is of the essence! Immediately disconnect the power and try to remove as much liquid as possible with a clean cloth or paper towel. Then, follow the cleaning steps outlined above, paying extra attention to drying the board thoroughly.

Q: My PCB has some corroded components. Can cleaning fix that?

A: Cleaning might help remove the corrosion, but it depends on the severity. If the corrosion is extensive, the components may be permanently damaged and need to be replaced. Use a specialized corrosion cleaner and be very gentle.

Q: How often should I clean my PCBs?

A: There's no hard and fast rule, but it depends on the environment. If the PCB is exposed to dust, humidity, or other contaminants, more frequent cleaning may be necessary. As a general guideline, inspect your PCBs periodically and clean them when you notice visible residue or signs of corrosion.