Spectacular Tips About What Is A PCB Code

How To Laser QR Code On PCB Board RayPCB

Decoding the Mystery

1. The Basic Breakdown

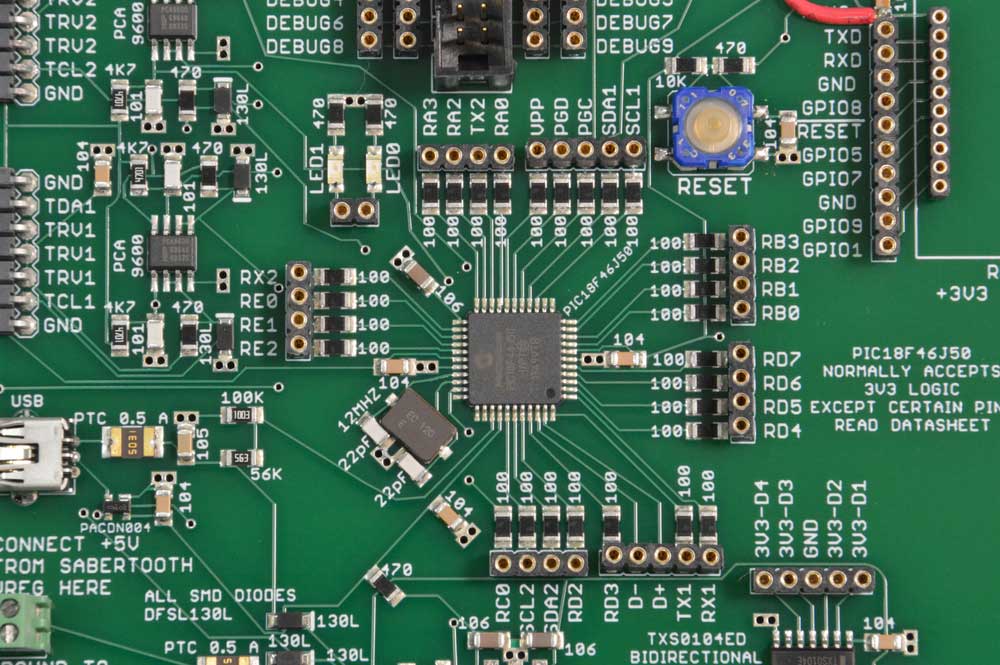

Ever peered at a printed circuit board (PCB) and noticed those cryptic markings? You're probably wondering, "What is a PCB code, anyway?" Well, think of it as a PCB's unique fingerprint. It's a combination of letters, numbers, and sometimes even symbols that tells you a whole lot about that little green (or sometimes other colors!) board. It's not just random gibberish; it's carefully constructed information designed to help manufacturers, designers, and even repair technicians understand the board's history, specifications, and purpose. It's kind of like the VIN number on your car, but for electronics! Without the PCB code, tracing back to manufacturing information can be a real headache, potentially costing valuable time and resources.

PCB codes arent a one-size-fits-all kind of thing. Different manufacturers, and even different departments within the same company, might use slightly different coding systems. This can lead to some initial confusion, but the core purpose remains the same: providing essential information about the PCB. And yes, sometimes deciphering them feels like cracking a secret code. But fear not, with a little understanding, you can learn to read these markings like a pro.

Now, you might be thinking, "Okay, I get that it's important, but what kind of information does it actually contain?" Good question! PCB codes can reveal the manufacturer, the date of production, the specific board type or model, the revision level (basically, how many versions of the design there have been), and even compliance information (like RoHS compliance, which means it's free of certain hazardous substances). All this data allows for traceability, quality control, and proper identification during assembly and repair. So, the next time you see a PCB code, remember its not just a jumble of characters; it's a story waiting to be told.

Imagine a scenario: a batch of PCBs starts malfunctioning after being installed in a product. Without a proper PCB code, pinpointing the source of the problem — whether it's a manufacturing defect, a design flaw, or a component issue — becomes a logistical nightmare. But with a clear and well-documented code, you can trace the board back to its origins, identify the specific batch, and quickly isolate the cause of the problem. This saves time, money, and potentially prevents widespread product failures. It's like having a digital breadcrumb trail leading you directly to the source.

PCB Clone Circuit Board Duplication, Copy Services

Peeling Back the Layers

2. Decoding the Data

So, we know PCB codes are informative, but what are the common elements you'll typically find? Think of it like this: each piece of the code has a specific meaning, like a mini instruction manual etched right onto the board. A common element is the manufacturer's identification, often represented by a short code or abbreviation. This helps you quickly determine who made the PCB, which can be crucial for warranty claims or resolving quality issues. Some PCB manufacturers even use their unique logo as part of the code.

Then there's the date code, which tells you when the PCB was manufactured. This is super important for identifying potential issues related to specific production runs or batches. Date codes can be formatted in various ways, such as year-week (YYWW) or year-month-day (YYYYMMDD). Knowing the manufacturing date allows you to track down specific production batches and quickly determine if a problem is widespread or isolated to a particular time frame. Imagine trying to find a needle in a haystack without knowing its location; that's what it's like trying to solve a PCB problem without a date code.

The board type or model number is another common piece of the puzzle. This identifies the specific PCB design and its intended application. This can be incredibly helpful when you need to order replacements or troubleshoot issues specific to a particular board type. The model number often correlates to the schematic or documentation associated with the PCB, making it much easier to find relevant information. Furthermore, the revision level indicates any changes or updates that have been made to the PCB design. This is critical for ensuring that you're using the correct documentation and that any fixes or modifications are applied appropriately.

Finally, you might find compliance information, such as RoHS (Restriction of Hazardous Substances) markings. This indicates that the PCB meets certain environmental standards and is free from specific hazardous materials. In today's world, compliance is a big deal, and having it clearly marked on the PCB can save you a lot of trouble. Compliance markings can also include certifications like UL (Underwriters Laboratories) or CE (Conformit Europenne), depending on the specific requirements for the intended market. So, the next time you see a PCB code, take a closer look — you might be surprised at how much information is packed into those seemingly random characters.

Understanding Air Conditioning Knowledge Of AC PCB PCBA Manufacturers

Where to Find These Elusive Codes on the PCB?

3. The Location Game

Alright, so now you know what a PCB code is and what it usually contains. The next question is: where do you actually find it on the PCB? It's not always in the most obvious spot! Often, manufacturers will place the code on the component side of the board, near a corner or along an edge. They might also place it on the solder side, though this is sometimes less common due to space constraints. It's usually printed using silkscreen ink, which is that white (or sometimes yellow) lettering you see on PCBs. However, sometimes, especially on smaller boards, the code may be laser-etched directly onto the surface.

The size of the PCB often influences where the code is located. On larger boards, you might find it printed in a relatively prominent location, while on smaller boards, it might be squeezed into a tiny corner. Sometimes, manufacturers even use multiple codes, placing one on the top side and another on the bottom. This redundancy can be helpful if one code becomes obscured or damaged. Its always a good idea to carefully inspect the entire board to make sure you haven't missed anything.

If you're having trouble finding the PCB code, try using a magnifying glass or taking a high-resolution photo with your phone. Sometimes, the lettering can be quite small, and the contrast with the board's surface may not be great. Using a bright light source can also help to illuminate the code and make it easier to read. In some cases, the code may be partially covered by components, so you might need to carefully inspect around those areas.

Finally, it's worth noting that some very small or densely populated PCBs may not have a code printed directly on them at all. In these situations, the code may only be found on the packaging or in the accompanying documentation. If you can't find a code on the board itself, be sure to check those alternative sources. Keep an eye out. It might be hidden in plain sight!

What Is PCB Traceability And Why It Needed?

Why Bother? The Benefits of Understanding PCB Codes

4. The Payoff

Okay, you might still be thinking, "Why should I even care about PCB codes?" Well, understanding them can save you time, money, and a whole lot of frustration! For starters, accurate identification of PCBs is crucial for inventory management. Knowing exactly what you have in stock prevents costly errors and ensures that you're using the right components for the job. Imagine ordering the wrong PCB for a repair and having to wait days (or even weeks!) for the correct one to arrive.

Troubleshooting and repair become significantly easier when you can quickly identify the specific PCB model and revision. This allows you to access the correct schematics, datasheets, and troubleshooting guides, making the repair process much more efficient. With the right information at your fingertips, you can diagnose problems faster and avoid unnecessary guesswork. In addition, traceability is essential for quality control and identifying the root cause of defects. If a batch of PCBs is found to be faulty, the PCB code allows you to trace them back to the specific manufacturing run, enabling you to quickly isolate the problem and prevent it from happening again.

Compliance and regulatory requirements are becoming increasingly important in the electronics industry. PCB codes often include information about compliance standards such as RoHS or UL, which can be crucial for ensuring that your products meet the necessary regulations. By understanding the compliance markings on the PCB, you can avoid potential legal issues and ensure that your products are safe and environmentally friendly. Furthermore, PCB codes are incredibly valuable for communication with manufacturers and suppliers. When ordering replacements or requesting technical support, providing the PCB code ensures that you're getting the correct parts and accurate information. This eliminates any ambiguity and prevents misunderstandings that could lead to delays or errors.

Think of it this way: A detailed PCB code provides crucial information about that components history. That history can be critical for maintaining electronic devices or duplicating devices with the same PCB. In short, understanding PCB codes empowers you to work more effectively with electronics, reduces errors, improves efficiency, and ensures compliance. It's a small detail that can make a big difference in your work.

Pcb Board Qlerocard

FAQ

5. Your Burning Questions Answered

Still have some questions lingering? Here are a few frequently asked questions about PCB codes:

6. Q

A: Not entirely. While there are common elements, the specific format and information included can vary depending on the manufacturer and the type of PCB. However, the goal is always the same: to provide essential information about the board.

7. Q

A: Absolutely! If you're designing and manufacturing your own PCBs, you'll need to establish a coding system that works for your needs. Consider including information about the manufacturer (if applicable), date of production, board type, and revision level. The important thing is to create a consistent and well-documented system that allows you to easily track and manage your PCBs.

8. Q

A: This can be a real headache! Try using a magnifying glass and a bright light to see if you can make out any of the characters. You can also try cleaning the area with a soft cloth and isopropyl alcohol to remove any dirt or grime. If all else fails, check the packaging or documentation that came with the PCB — the code may be listed there. If you still can't find it, you might need to contact the manufacturer or supplier for assistance.