Unique Info About What Is BOM For Material Sap

Unlocking the Secrets of BOM in SAP Materials

1. What exactly is a BOM?

Ever wondered how a complex product like a car or even a seemingly simple gadget gets made? The answer often lies in something called a Bill of Materials, or BOM. Think of it as a recipe, but instead of flour, eggs, and sugar, we're talking about raw materials, components, and sub-assemblies. It's a comprehensive list that spells out everything you need to build something, from the tiniest screw to the most significant part, and how much of each is required. It's essentially the DNA blueprint of your product.

In SAP (Systems, Applications & Products in Data Processing), a BOM isn't just a list; it's a structured, digital record. It's the backbone of your material management and production planning processes. When you have a well-defined BOM in SAP, you can efficiently manage inventory, plan production schedules accurately, and even calculate costs with precision. It acts as a single source of truth, ensuring everyone from engineering to purchasing is on the same page, literally.

Why is all this important? Imagine trying to bake a cake without a recipe. You might end up with something edible, but chances are it won't be what you intended! Similarly, trying to manufacture a product without a proper BOM can lead to material shortages, production delays, and increased costs — nobody wants that! A good BOM prevents these headaches by providing a clear roadmap for creating your product.

So, if you are new to BOMs, don't be intimidated. We'll break it down so that even someone who's never touched SAP before can grasp the basics. Get ready to dive into the wonderful world of materials, structures, and the all-powerful Bill of Materials!

Finished Product Codes In Sap At Susan Guthrie Blog

The BOM's Role in SAP Material Management

2. Why is BOM crucial to material management?

In the grand scheme of SAP, the BOM is a star player in material management. It's not just about knowing what ingredients go into your product; it's about connecting that information to the entire supply chain. Think of it as the central nervous system that controls the flow of materials within your organization. It helps you track everything from raw materials to finished goods with seamless integration.

For instance, let's say you need to manufacture 100 widgets. With a BOM defined in SAP, the system can automatically calculate the exact quantities of each component needed. This triggers purchase requisitions for raw materials, alerts warehouse staff for parts picking, and updates inventory levels in real-time. Without a BOM, this process would be manual, error-prone, and incredibly time-consuming.

Moreover, BOMs play a vital role in cost accounting. By linking material costs to individual components in the BOM, SAP can calculate the standard cost of your finished product. This information is crucial for pricing decisions, profitability analysis, and cost control. So, a well-maintained BOM doesn't just help you make things; it also helps you make money.

By centralizing all of this information, a BOM enables better decision-making, reduces waste, and optimizes the entire production process. This means faster production cycles, lower costs, and happier customers. In a world where efficiency and agility are key, a robust BOM in SAP is a game-changer.

Types of BOMs in SAP

3. Understanding the diverse BOM types in SAP

Believe it or not, there's more than one type of BOM in SAP. It's not a one-size-fits-all situation! Depending on your industry, product complexity, and specific manufacturing processes, you might need to use different types of BOMs. Understanding these differences is critical for leveraging the full potential of SAP's BOM functionality.

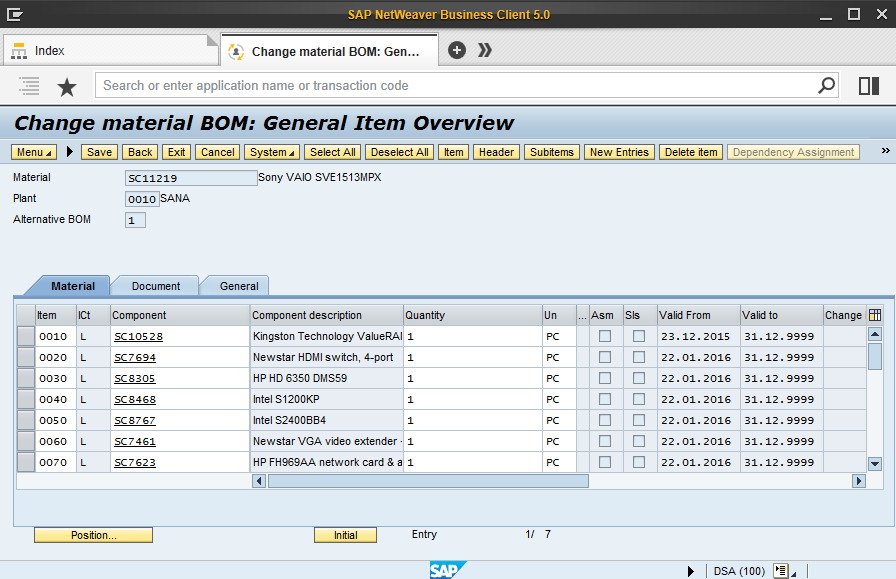

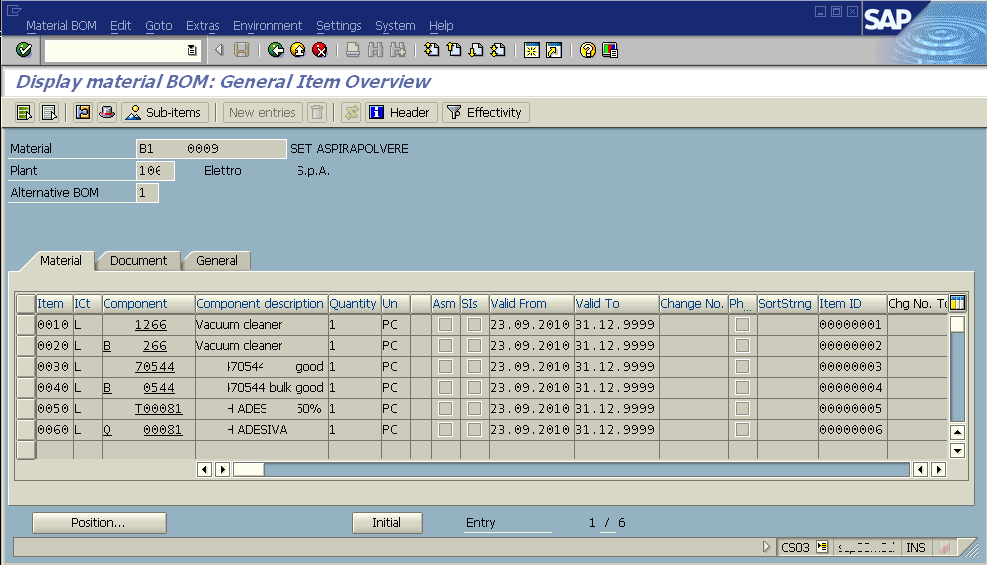

One common type is the "Material BOM," which is the standard bill of materials we've been discussing so far. This BOM lists all the components required to manufacture a specific material. Another type is the "Sales Order BOM," which is dynamically created based on the customer's order. This BOM might include options or customizations specified by the customer, making each sales order unique.

Then there's the "Equipment BOM," which is used to maintain equipment or machinery. This BOM lists all the spare parts, components, and tools required for maintenance and repairs. Similarly, a "Functional Location BOM" is used to track the components associated with a specific location within your facility.

The variations can seem overwhelming, but the key is to choose the BOM type that best fits your specific business needs. SAP is flexible enough to accommodate a wide range of scenarios, whether you're manufacturing complex machinery or providing customized products to individual customers. Choosing the right BOM sets you up for efficient management throughout the production life cycle.

SAP Help Portal

Creating and Maintaining BOMs

4. How to get it right?

Creating a BOM in SAP is like building a house; you need a solid foundation and careful attention to detail. A poorly constructed BOM can lead to all sorts of problems down the line. So, let's talk about some best practices for creating and maintaining BOMs in SAP.

First and foremost, accuracy is paramount. Double-check every component, quantity, and unit of measure. Errors in the BOM can ripple through your entire supply chain, causing material shortages, production delays, and cost overruns. Consider implementing a review process to ensure the BOM is accurate before it's released to production. A little upfront effort can save you a lot of headaches later.

Secondly, keep your BOMs up-to-date. Products evolve, components change, and designs get modified. Make sure your BOMs reflect these changes in a timely manner. Implement a change management process to track revisions and ensure that everyone is working with the latest version of the BOM. This is where using version control features within SAP can be invaluable.

Collaboration is also key. Involve stakeholders from different departments — engineering, procurement, production, and quality — in the BOM creation and maintenance process. This ensures that everyone has a voice and that the BOM reflects the needs of the entire organization. A team approach can help you catch errors, identify opportunities for improvement, and build consensus.

Remember, a well-maintained BOM is a living document. It requires ongoing attention and refinement. By following these best practices, you can ensure that your BOMs are accurate, up-to-date, and aligned with your business goals. It's an investment that pays off in the form of increased efficiency, reduced costs, and improved customer satisfaction.

![[SAP] PP模块 BOM ( Bill Of Material)_bom属于sap哪个模块CSDN博客 [SAP] PP模块 BOM ( Bill Of Material)_bom属于sap哪个模块CSDN博客](https://img-blog.csdnimg.cn/2020061008540696.png?x-oss-process=image/watermark,type_ZmFuZ3poZW5naGVpdGk,shadow_10,text_aHR0cHM6Ly9ibG9nLmNzZG4ubmV0L3dlaXhpbl80NTI4MTAyMw==,size_16,color_FFFFFF,t_70)

[SAP] PP模块 BOM ( Bill Of Material)_bom属于sap哪个模块CSDN博客

BOM Challenges and Troubleshooting

5. What to do when things go wrong?

Even with the best practices in place, you might encounter challenges with BOMs in SAP. It's part of the process. Knowing how to troubleshoot common issues can save you time and frustration. Let's look at some of the most frequent problems and how to solve them.

One common challenge is data inconsistency. This can happen when different departments use different naming conventions or units of measure. For example, engineering might refer to a component as "Bolt-M8x20," while purchasing calls it "M8 Bolt, 20mm." These inconsistencies can lead to errors in the BOM and problems with procurement. To address this, establish standardized naming conventions and units of measure across the organization and train users to follow them consistently.

Another issue is BOM complexity. For complex products with hundreds or thousands of components, managing the BOM can become overwhelming. Break down the BOM into smaller, more manageable modules. Use sub-assemblies to simplify the structure and make it easier to navigate. Also, leverage SAP's BOM reporting and analysis tools to identify areas for improvement.

Incorrect component quantities can also be problematic. These are often human errors, so implement validation checks and review processes to catch these mistakes early. Consider using SAP's automatic BOM explosion functionality to calculate component quantities based on the production quantity. This can help reduce the risk of errors.

The solution often lies in clear communication, robust processes, and a willingness to learn from mistakes. By addressing these challenges proactively, you can keep your BOMs accurate, up-to-date, and effective. A little bit of troubleshooting know-how can go a long way in ensuring that your production processes run smoothly.

![FREE 23+ Bill Of Materials (BOM) Templates [EXCEL, WORD] FREE 23+ Bill Of Materials (BOM) Templates [EXCEL, WORD]](https://www.dailylifedocs.com/wp-content/uploads/2022/03/BOM-Template-2578919-1024x752.jpg)

FAQ

6. Frequently Asked Questions

Let's tackle some of those questions that might be swirling around in your head about BOMs. I've compiled the most frequently asked questions to give you clear and concise answers.

Q: What's the difference between a single-level BOM and a multi-level BOM?A: Think of a single-level BOM as a basic recipe. It lists only the immediate components needed to make a product. A multi-level BOM, on the other hand, is like a detailed cookbook with sub-recipes. It shows the entire hierarchy of components, including sub-assemblies and their respective components. Multi-level BOMs are used for more complex products with multiple layers of assembly.

Q: How do I handle engineering changes in the BOM?A: SAP provides change management functionality specifically for BOMs. You can create engineering change requests to track proposed changes, approve or reject them, and implement them in the BOM. The system maintains a history of all changes, so you can always see what was changed, when, and by whom. This ensures traceability and accountability.

Q: Can I use BOMs for planning purposes in SAP?A: Absolutely! BOMs are essential for material requirements planning (MRP) in SAP. MRP uses the BOM to calculate the quantities of raw materials and components needed to meet production demands. This helps you plan your purchases, manage inventory levels, and ensure that you have the right materials on hand when you need them. It's all about optimizing your supply chain and avoiding shortages or overstocks.

Q: How does SAP BOM relate to product lifecycle management (PLM)?A: Great question! SAP BOM is deeply intertwined with PLM. PLM systems manage all the information about a product throughout its entire lifecycle, from design and engineering to manufacturing and service. SAP BOM is an integral part of the PLM process, providing the manufacturing view of the product structure. When design changes are made in the PLM system, these changes are typically reflected in the SAP BOM to ensure alignment between engineering and production.